Disney Research Creates Layered Fabric 3D Printer

Disney Research has recently revealed its Layered Fabric 3D Printer in collaboration with Carnegie Mellon University. This new 3D printer comes after the research arm of The Walt Disney Company revealed its needle-felting machine last year.

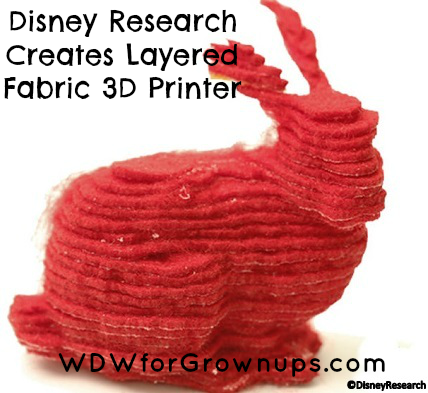

A felt bunny created by the new 3D printer from Disney Research

A felt bunny created by the new 3D printer from Disney Research

This new Layered Fabric 3D Printer breaks down a 3D model into slices and translates them into the printer. The printer then uses a laser to cut the outline of each layer from a roll of felt. Once that layer is on the print bed, heat-sensitive adhesive is activated.

As the process is repeated the object is printed and the end product is a soft and flexible layered object like the "Standford bunny" in the photo above. The bunny took nearly two and a half hours to print.

The drawbacks to the process include a lot of waste material and the fact that the layers are more pronounced on smaller objects like the 3D bunny.

Disney Research unveiled the Layered Fabric 3D Printer at the Conference on Human Factors in Computing in Seoul, South Korea.

What do you think about the technology behind this new 3D printer? Let us know in the comments.

Kristen K. wrote on Thu, 04/23/2015 - 23:53:

I think this is so cool! While I wouldn't want something made like this, it's going to be amazing for making new prototypes of plush, and I love the interactive elements that they can use!

Post new comment